Efficiency Working Of Khakhra Making Machines

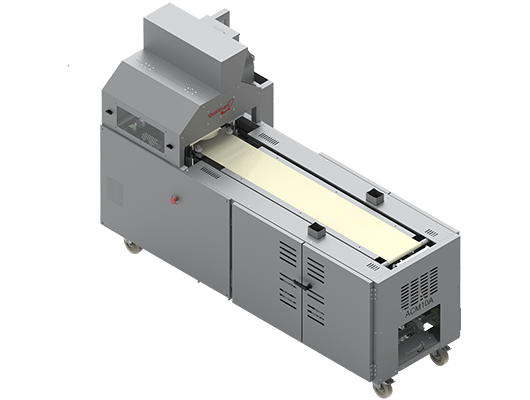

Khakhra is a thin, crispy flatbread typically made from wheat flour and various spices. This is a popular Indian snack comes in different flavours and styles. Some popular variations include masala khakhra, methi khakhra and jeera khakhra, each featuring different spice blends. This snack is considered a relatively healthy snack option compared to deep-fried snack because it is usually roasted or baked. It’s low in fat and often high in dietary fibre due to the wheat flour. A high-capacity khakhra-making machine is designed to streamline the production of khakhra, a popular Indian snack. These machines are equipped with several key features to enhance efficiency and quality. These machines are built to handle large quantities of khakhra production, typically ranging from hundreds to thousands of pieces per hour. They often come with an automatic dough feeding system, which reduces manual labour and ensures thickness. High-capacity machines use rotary pressing mechanisms to uniformity flatten and cook the khakhra. This results in even cooking and crispiness. Precise temperature control is crucial for achieving the desired texture and taste. These machines have advanced temperature control systems to maintain the right cooking conditions.

Users can often adjust the thickness of the khakhra, allowing for customization based on customer preferences. Some models have a continuous conveyor system that moves the khakhra through various cooking stages, ensuring efficient and uniform cooking. These machines may include an oil application unit for even distribution of oil, enhancing flavour and texture. Some machines automate the stacking processes. Hygienic is crucial in food production, these machines are often constructed from stainless steel, which is easy to clean and maintain. They come in equipped with safety features like emergency stop buttons and protective guards to ensure the well-being of operators. Depending on the manufacturers, these machines may offer customization options to meet specific production requirements. User-friendly interfaces and controls make these machines accessible to operators with minimal training. Many models are designed for minimal maintenance, reducing downtime and operational costs. These machines help maintain consistent quality in khakhra production, meeting customer expectations. They are often designed to meet food safety and hygiene standards, ensuring the product is safe for consumption. These machines are sophisticated piece of equipment designed to increase production efficiency while maintain product quality and safety standards. These machines are ideal for businesses looking to scale- up their khakhra production.

On the contrary, here are some key features and components typically found in a roti-making machine. Roti, a flatbread commonly consumed in Indian household. These machines are used to make soft and puff rotis, which include dough preparations. Then the dough automatically portion into uniform-sized balls, ensuring consistent roti sizes. Then the machine undergoes the dough flattening process. A heating element in the machine cooks the flattened dough sheets and puffs up the rotis; other features like temperature control, adjustable thickness, speed control, stacking and collection and safety features helps to automate and streamline the process of making rotis, while increasing production efficiency.

Comments

Post a Comment